Prevent static shocks on blown film lines

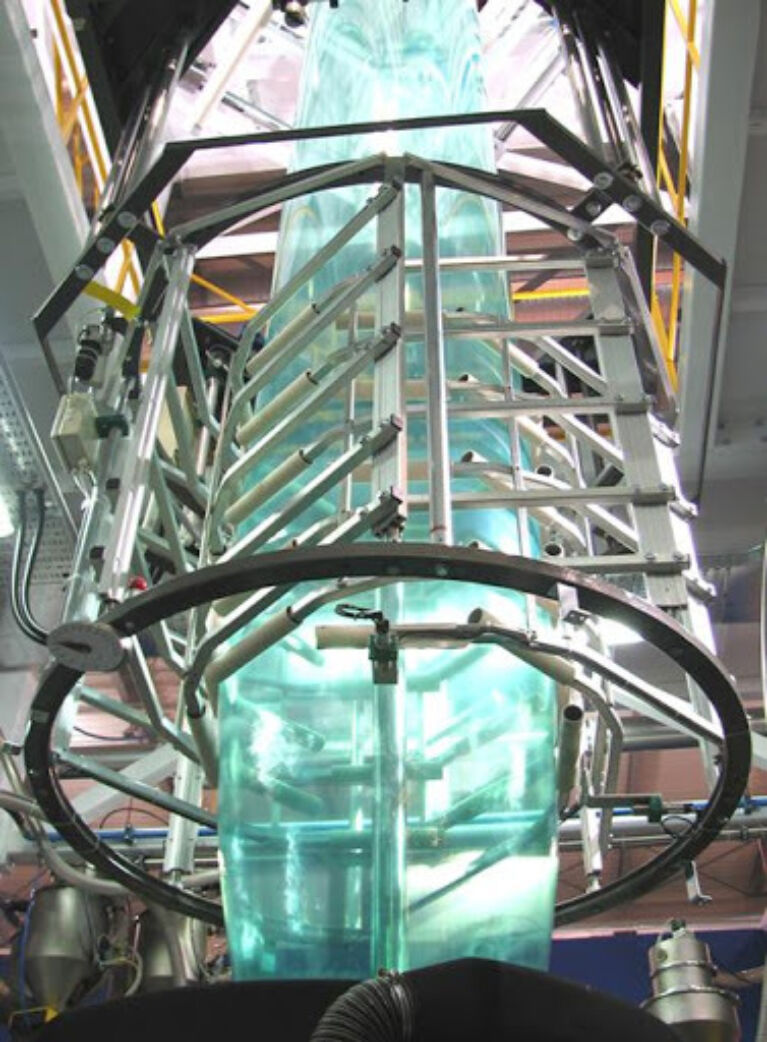

After the material passes the nip (top) rollers on the blown film line it is generating static electricity and building up high static charges. This due to friction by passing several rollers and temperature fluctuation because the material is cooling down. If the material passes a corona treater, a massive static charge is created on the material. Here an extra section of static eliminators, preferably with inline static measuring (Close Loop Feedback), is recommended.

On the final winder(s) long range static elimination bars are installed to neutralise the material during winding. Applying theThunderION 2.0 IQ static eliminator will guarantee that the complete material is neutralised. Starting as small diameter to end as large diameter rolls.

This will prevent dust-attraction, telescoping of the end roll and unpleasant static shocks to the operator. When winding double layer (tube) material, static elimination is essential to be able to open the material after unwinding. Sometimes discharging before winding is needed to reach a low static charge on the end roll. Normally 24V static eliminators are used for discharging here

After the material passes the nip (top) rollers on the blown film line it is generating static electricity and building up high static charges. This due to friction by passing several rollers and temperature fluctuation because the material is cooling down. If the material passes a corona treater, a massive static charge is created on the material. Here an extra section of static eliminators, preferably with inline static measuring (Close Loop Feedback), is recommended.

On the final winder(s) long range static elimination bars are installed to neutralise the material during winding. Applying the ThunderION 2.0 IQ static eliminator will guarantee that the complete material is neutralised. Starting as small diameter to end as large diameter rolls.

This will prevent dust-attraction, telescoping of the end roll and unpleasant static shocks to the operator. When winding double layer (tube) material, static elimination is essential to be able to open the material after unwinding. Sometimes discharging before winding is needed to reach a low static charge on the end roll. Normally 24V static eliminators are used for discharging here.

The pollution of the static eliminators is a critical issue. To avoid a drop in efficiency this level can constantly be monitored by the Manager IQ System.

If the efficiency drops below a pre-defined level, the operator/PLC receives a warning. Maintenance will be indicated on the polluted static bars.

For more intelligence, the Manager IQ System can be directly connected to the Blown film line via a Fieldbus connection. This is how all essential information is collected regarding the efficiency and required maintenance of the static equipment. Also the level of static charge on the material is collected and logged.

This all results in high quality, competitive production of blown film.