Problems and solutions for static electricity in rotogravure printing

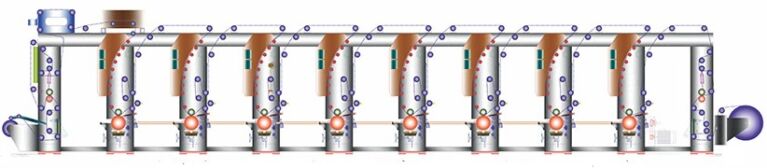

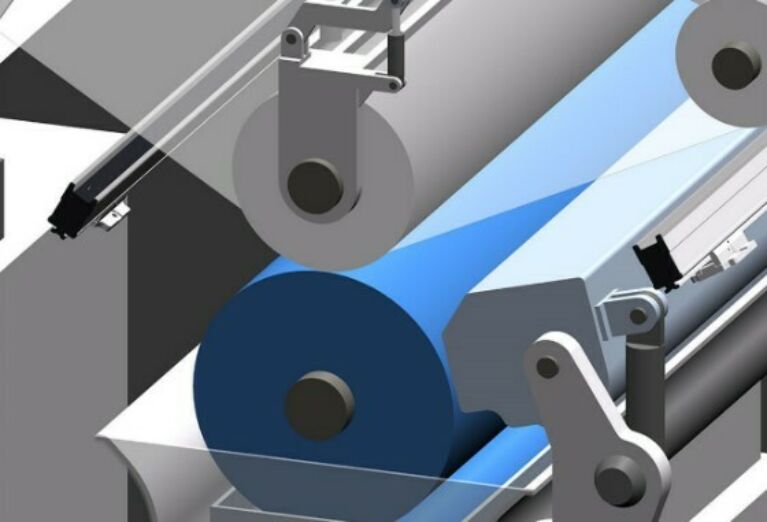

Rotogravure printing is specially developed for large, to very large graphic runs by using a rotogravure press. During the gravure printing process the printing cylinder rotates in the ink pan where the engraved cells fill with ink. As the cylinder rotates clear of the ink pan, any excess ink is removed by the doctor blade. Further around, the cylinder is brought into contact with the substrate, which is pressed against it by the rubber covered impression roller.

An electrostatic charge is created on the surface of the material, as it travels through the printing machine with continued contact and separation events, complicated by the speed of the process. The surface charge can build to potentially hazardous levels at the rotogravure print section, where the use of solvent based inks creates a dangerous situation. A spark from an electrostatic discharge can ignite the solvent/oxygen mixture, which ultimately can cause a fire. ATEX approved static eliminators will neutralise these static charges before and after the print station, allowing for static free and safe rotogravure printing. Simco-Ion also recommends static control equipment at the unwinder and winder sections, to avoid shocks to operators and the attraction of dust particles, caused by static electricity.

Inside each printing section the material passes multiple rollers and a static charge is created. ATEX approved static eliminators, such as the Performax Easy (IQ) EX, are neutralising the electrostatic charge before and after printing to prevent static charge acting as a possible ignition source. Pollution on the static eliminator, by ink or dust, is recognised so the static efficiency level per printing station can be monitored by the Manager IQ. If the efficiency goes below a preprogramed level, the operator receives a warning so he can service the indicated static eliminators.

At the winding section the material can once again create high static charges due to the pressure rollers and causing operators to get shocks when near to the material and creating the telescoping effect on the end rolls. As the distance to the material changes at the winder, a ThunderION 2.0 IQ or Performax Easy IQ static eliminator is required to effectively eliminate the static charges created during the final winding. Additional demands like a predefined static level or ensuring personnel safety, by using a IQ Manager System with inline static measurement and Closed Loop Feedback-technology, is possible.

The Manager IQ can be directly connected to the printing line PLC via Fieldbus connection. An alarm alerts the operator in case the electrostatic charge reaches a dangerous level.

The Manager IQ System provides all essential information to increase personnel safety and reduces the chance on fires to a minimum, so high quality and competitive rotogravure printing is guaranteed.