COF Tester / Coefficient of friction tester / Peel tester

Coefficient of friction (COF) testing measures how easily two surfaces slide against each other. In packaging, paper, films, and board, COF testing is essential to ensure stable stacking, reliable machine feeding, and consistent product quality. COF is typically measured according to international ISO standards using specialised laboratory testing equipment.

What is the Coefficient of Friction?

The coefficient of friction describes the resistance between two surfaces in contact when one surface moves over the other. A controlled coefficient of friction is critical in industrial processes where materials must slide smoothly, but not uncontrollably.

Inconsistent friction values can lead to production stoppages, unstable stacks, or transport issues. For this reason, COF is a key quality parameter in many European manufacturing and packaging environments.

Static vs Dynamic Coefficient of Friction

Static coefficient of friction

-

Resistance to the start of movement

-

Important for stack stability and pallet safety

Dynamic coefficient of friction

-

Resistance during continuous movement

-

Important for transport, feeding, and processing on machines

Coefficient of Friction Testing Equipment

FP-2260 Friction/Peel tester - Coefficient of friction tester (COF)

Application: paper & pulp, cardboard, package testing overview

Property: adhesion & tack testing, coefficient of friction testing, seal strength

Horizontal tensile machine

Application: paper & pulp, cardboard

Property: coefficient of friction testing, tensile - universal testing machine (utm)

Rycolab Coefficient of Friction Tester - COF Tester

Application: paper & pulp, cardboard

Property: coefficient of friction testing

Rycolab Inclined Surface Coefficient Of Friction Tester

Application: paper & pulp, cardboard

Property: coefficient of friction testing

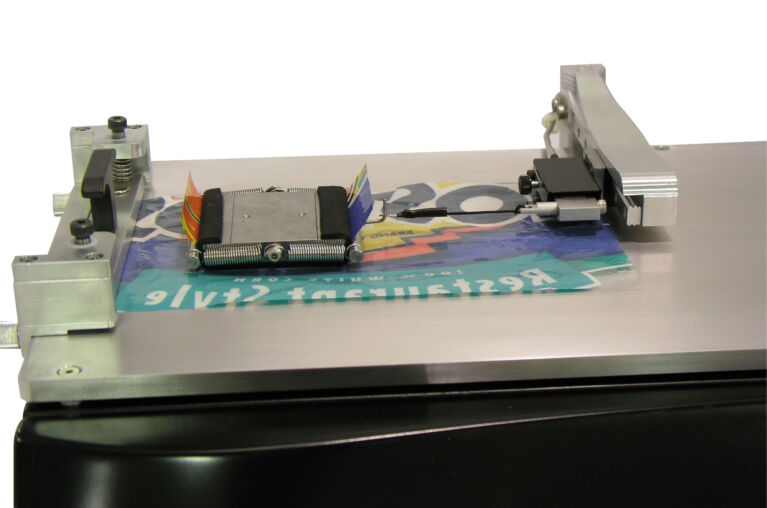

COF Sleds

COF Sled

Application: cof sleds

Property: coefficient of friction testing

Spring COF Sled

Application: cof sleds

Property: coefficient of friction testing

Heated Platen COF Sleds

Application: cof sleds

Property: coefficient of friction testing

EZ-Sled for COF Testing

Application: cof sleds

Property: coefficient of friction testing

Self Adjusting Sled for COF

Application: cof sleds

Property: coefficient of friction testing

Frequently Asked Questions About COF Testing

What is the coefficient of friction (COF)?

The coefficient of friction describes the resistance between two surfaces when one slides over the other. It indicates how easily materials move relative to each other.

What does a high or low COF mean?

A high COF means surfaces resist sliding, while a low COF means they slide easily. The required COF depends on the application and handling conditions.

Is coefficient of friction the same as slip?

Slip is a general term describing movement between surfaces. COF testing quantifies slip by measuring static and dynamic friction values.

What is static coefficient of friction?

Static COF is the force required to start movement between two surfaces that are at rest.

What is dynamic coefficient of friction?

Dynamic COF is the force required to maintain movement once sliding has already started.

Which is more important: static or dynamic COF?

Both are important. Static COF affects stack stability, while dynamic COF affects machine feeding and transport.

Why is COF testing important in packaging?

COF testing ensures packaging materials feed reliably on machines, stack safely, and do not slip during transport.

How does COF affect packaging line efficiency?

Incorrect COF values can cause jams, misfeeds, or unstable product flow, reducing line efficiency.

Is COF testing used for paper and board?

Yes, COF testing is commonly used to evaluate handling, stacking, and processing behaviour of paper and board.

Is COF testing relevant for plastic films?

Yes, plastic films often require controlled slip properties to perform consistently in production and packaging.

How is coefficient of friction measured?

COF is measured by pulling a weighted sled across a test surface and recording the force required to start and maintain movement.

Does COF depend on surface conditions?

Yes, surface texture, coatings, humidity, and contamination can all influence COF results.

Can COF values change over time?

Yes, ageing, storage conditions, and surface treatments can cause COF values to change.

What is a COF tester?

A COF tester is a laboratory instrument designed to measure static and dynamic coefficient of friction under controlled conditions.

Can one tester measure both static and dynamic COF?

Yes, most professional COF testers measure both values in a single test.

What materials can be tested for COF?

Common materials include paper, board, plastic films, foils, textiles, and coated surfaces.