Dust problems

Problem

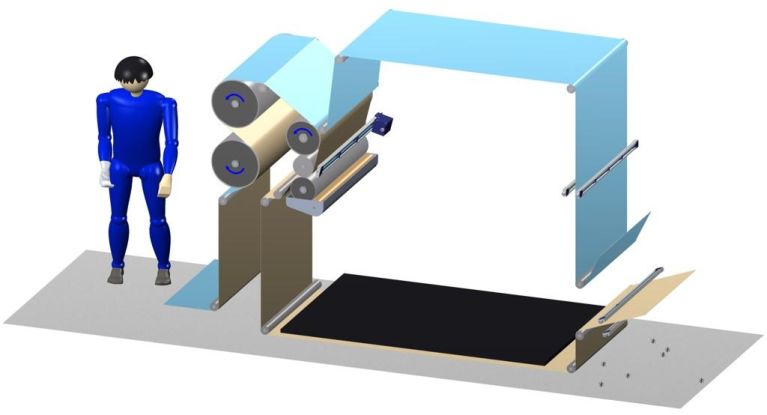

Static charge on a material can build up along the process. Friction between idle rollers and film creates a charge. Each new friction accumulates charge. Charges can rapidly become very high. Charges over 100 kV are not uncommon. Static charge on a material will attract particles from the surrounding. This is usually dust, but can also be other contaminates including small flies. In most cases this is unwanted and should be prevented. Special care should be taken when films run close to the floor because attraction of dust is inevitable.

Solution

Place anti static equipment at various strategic locations along the production process.