What is Phenolic Yellowing

Phenolic Yellowing is a phenomenon usually observed after periods of storing or transporting white, pale or pastel colored textiles. White, pastel and pale colored textiles are all potentially susceptible to phenolic yellowing (sometimes called Elusive Yellowing as it can fade once the textile is exposed to sunlight and air).

It is caused when Nitrous Oxides react with yellowable phenolic compounds on the surface of the textile. The source of the Nitrous Oxide contamination is usually the bi-products of combustion, such as diesel-powered fork lifts, heaters, or road traffic pollution. Other sources of nitrogen on the fabric surface are amine based softeners. The yellowable phenols often come from cheap antioxidants, such as BHT, which are present in the plastic covers that are used to protect the garments or rolls of fabric. If the fabric is contaminated with nitrous oxides, and then covered with a BHT containing film, then over time the antioxidant can leach from the packing material on to the surface of the textile and react with the nitrous oxide contaminants, resulting in phenolic yellowing. This reaction is accelerated if there is increased temperature, moisture content or a more alkaline fabric pH.

How do we test Phenolic Yellowing?

The SDL Atlas Phenotest Kit is a combination of 3 products which are used to create the perfect conditions to promote phenolic yellowing.

These 3 products are

- High grade filter papers which have been impregnated with a Nitrophenol compound

- A BHT free Polythene Sheet

- A Control Fabric which is known to significantly yellow in a phenolic yellowing test.

The fabric which is being tested in placed in intimate contact with the impregnated test papers, for a period of 16 hours at 50˚C whilst the whole package is wrapped in the BHT free film. This is defined in the ISO 105-X18 testing standard. The Nitrophenol compound will then react with any alkalinity, moisture or other phenolic yellowing causing contaminant on the fabric, and if these are present, then the fabric will yellow during the test.

The result of the test will tell the fabric producer whether they need to take any corrective action to reduce the chance of the fabric yellowing in practice. This is usually to wash and to adjust the fabric pH to around 6.5. Also, the manufacturer would ensure that the sources of contamination are removed, such as not using any combustible fuels in the warehouse, ensuring no fumes from outside of the warehouse can enter, and ensuring unstable antioxidants are not used in packing materials.

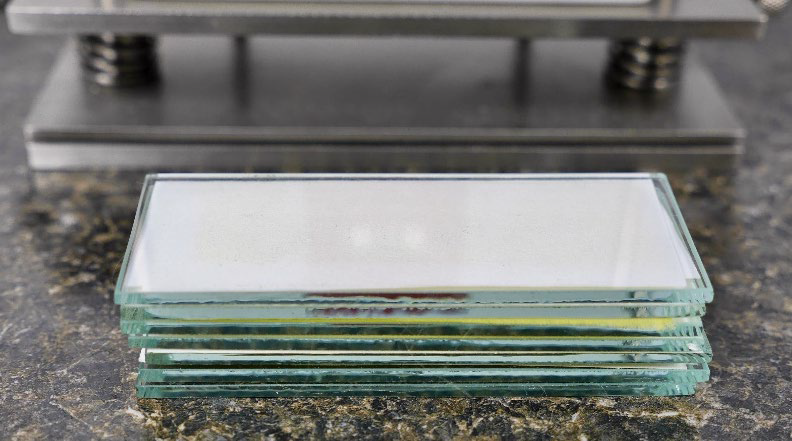

The samples and control are folded into the test paper and stacked between glass plates.

The glass plates are then wrapped and sealed into a piece of the BHT free plastic.

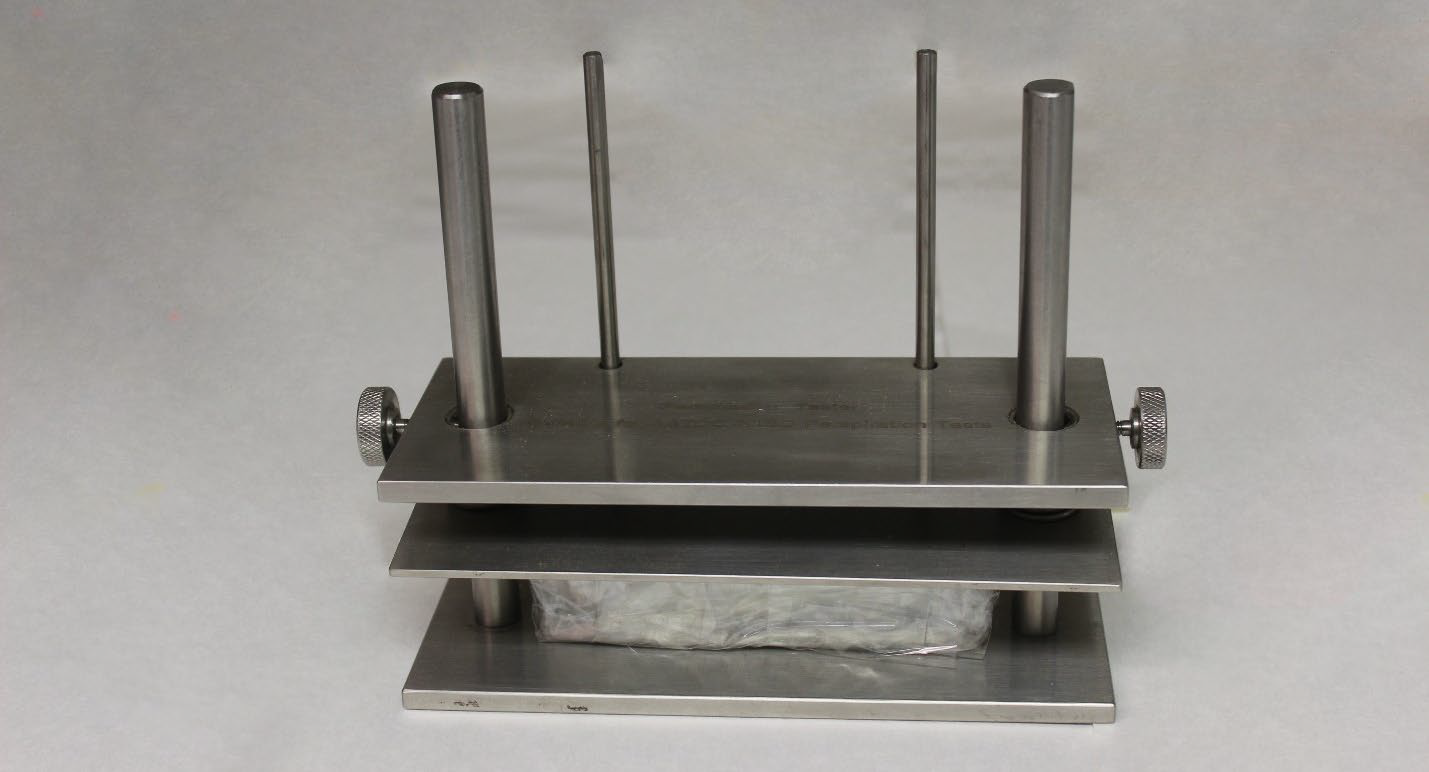

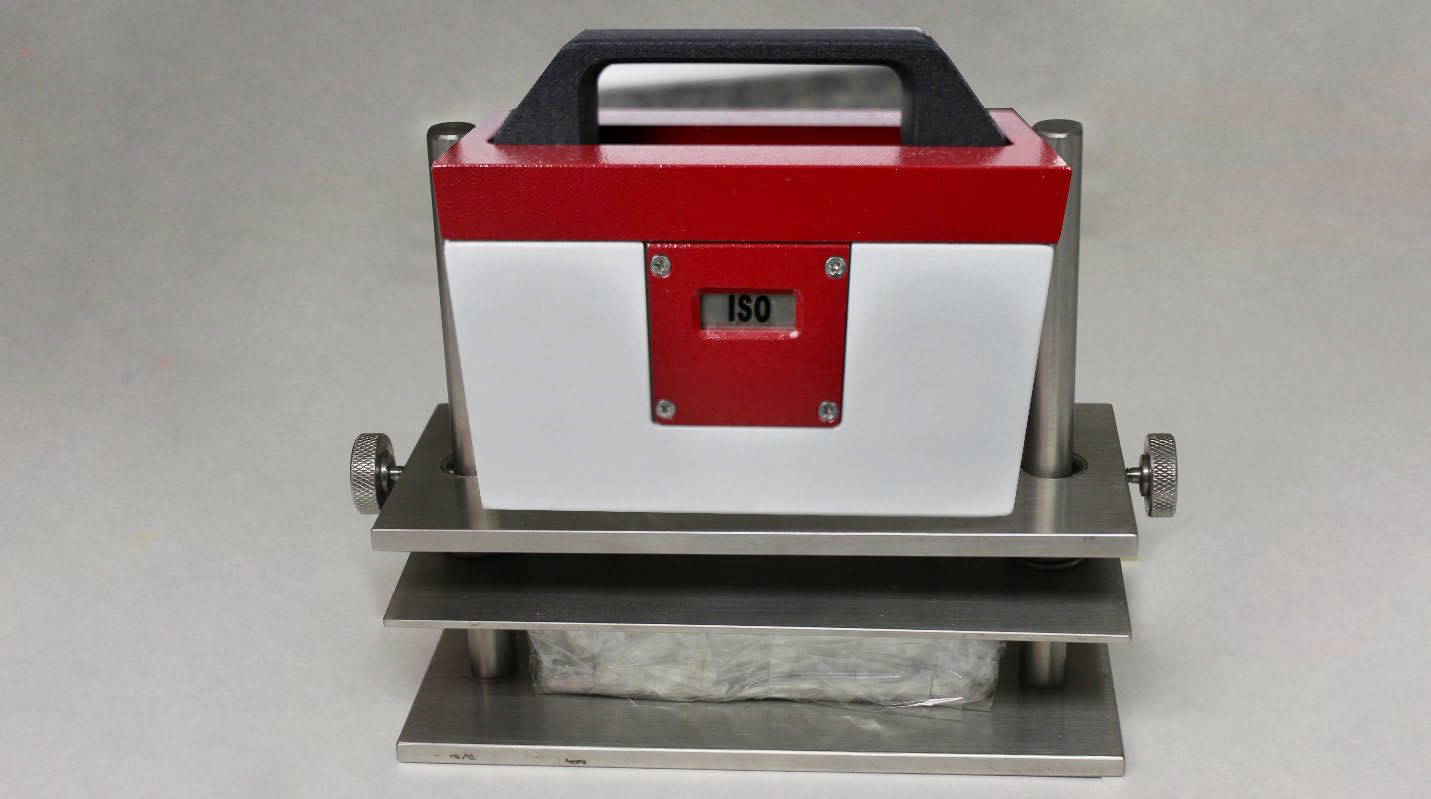

The wrapped plates with samples are then placed into the Perspiration Tester.

The approriate weight is placed on top of the Perspiration tester in order to apply consistent pressure to the wrapped samples. The plates are then clamped into place by turning the dials on the instrument’s sides. The weight is then removed and the Perspiration Tester is placed in the Laboratory Oven (G209A/B) for 16 hours.

How to interpret the results?

We should be clear that this test assesses the POTENTIAL that the fabric could be susceptible to Phenolic Yellowing. We have to remember that a range of factors need to be present for Phenolic Yellowing to happen at all.

The Phenotest Kit is providing all the necessary ingredients for a contaminated, alkaline, or otherwise susceptible fabric to yellow. In effect we are assessing the RISK that a fabric could yellow if the conditions allow.

Retailers will have a pass/fail grade for the amount of yellowing risk they are prepared to accept. This is usually grade 4 or above (4, 4-5 or 5) based on the how yellow the fabric has become after the test. A grade 4 will seem visually very yellow, so we need to remember that this test is assessing the POTENTIAL to yellow, given the correct conditions.

What do the grades mean?

A grade 4 actually means the risk or potential of yellowing is low or acceptably low. A grade 1 would mean the risk or potential of yellowing is very high. In reality a fabric achieving a grade 1 may not yellow at all in the real world, if the manufacturer is breaking the chain of contaminants which are needed for Phenolic Yellowing to occur. But it would only take a slight issue and that fabric could yellow.

On the other hand, a grade 4 would suggest that the fabric is more stable and much more contamination would be required before it started to yellow. A retailer wouldn’t accept any visible yellowing on the products in store, so it is incredibly important that they are testing the potential for their products to yellow prior to shipping. It also gives the manufacturer confidence that the product will resist yellowing and they will not face any penalties and loss of profits from customer/retailer complaints. Garments spend many weeks in shipment containers and then potentially many weeks in the retailer's distribution warehouses. It is vital that a Phenolic Yellowing test is performed to minimize the risk of both parties.